HydroGuard Mini

The Problem

Deposition of grit and assorted debris occurs within both foul and surface water systems, provides frequent problems for maintenance teams. Some of the reasons for the depositing of material within pipes can be:

- Large pipe diameters with small dry weather flow rates (made worse by water saving initiatives).

- Poor gradients which do not provide self cleansing velocities.

- Sagging of pipes by geological influences or settlement.

- Attenuation systems which by design allow settlement of solids.

This can result in higher pollutant loading at storm overflows, intermittent biological loads to sewage treatment plants, odour problems, a reduction of hydraulic capacity of the pipes or damage of the pipes by sulphur corrosion.

In addition, the designed retention volume of most combined sewer networks cannot be activated on rainfall events, as volume has been taken up by the deposits, which may also cause premature operation of storm overflows.

The Solution

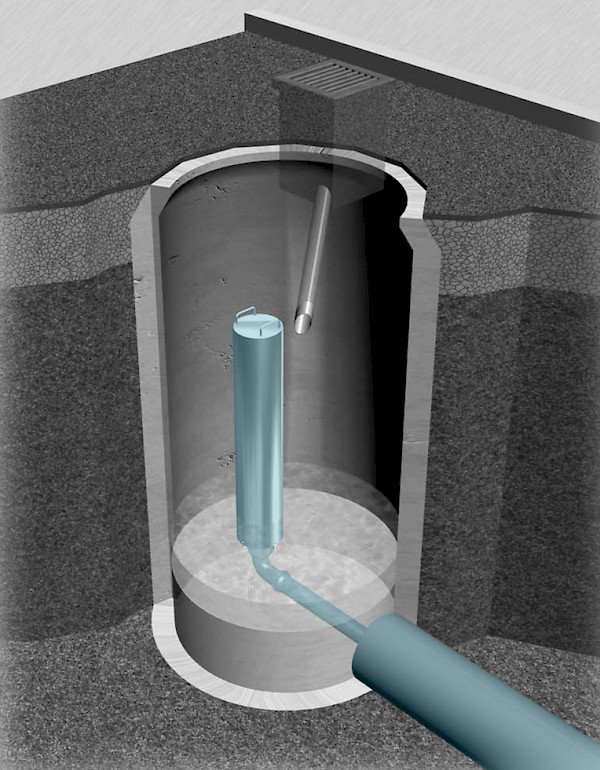

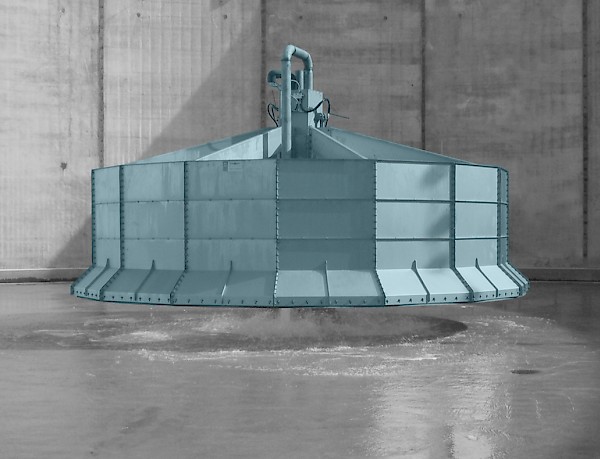

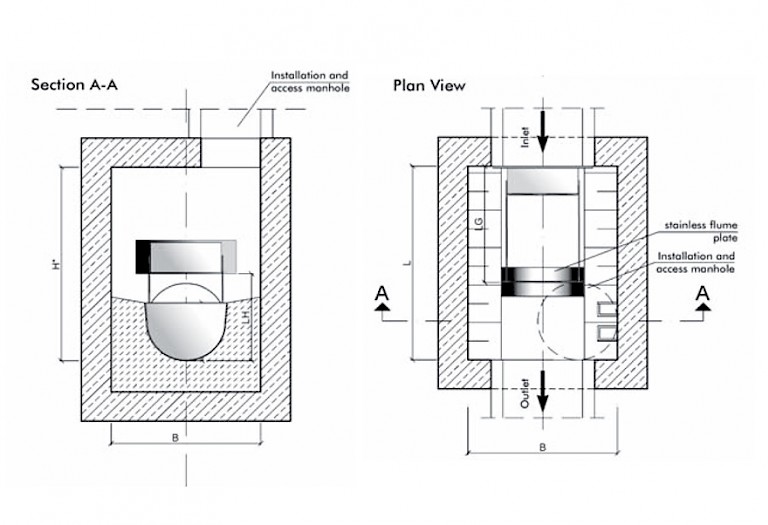

The HydroGuard® MINI (HGM) is a mechanical device for continuous, automatic and operational cleaning of medium sized pipes (DN 500 – 2500).

Using HGM, the frequency of overflow spills are reduced, by ensuring that the conveying sewer is kept clear of silt deposits which maximises the pipe capacity.

The biological loading passing down to the treatment plant is equalized, throughout dry weather periods, by the regular flushing of settled debris, preventing ‘shock loading’ at the beginning of rainfall events.

Other benefits of regular flushing with HGM are:

- The lifespan of sewer pipes is extended.

- Annoying odours are avoided.

- Regular Tanker flushing maintenance can be significantly reduced or completely cancelled.

The continuous flushing of the foul sewer using dry weather flow prevents the build-up of silts. The pipe sections downstream of the flusher are cleaned by the generation of a powerful flushing wave from the HGM. The upstream pipeline, used to impound the flushing water, is cleaned using the energy produced by the sudden falling water-level and the increase of velocity, re-suspending any settled debris (Downsurge Flush).

Within Surface water attenuation systems, the HGM can be programmed to store the flushing water at the top of the system. This is then released after the tank has drained down, allowing the silts and grits to be washed away. This is particularly effective to ensure that any downstream flow regulator is kept clean and free from debris collection.

The HGM can also be used to provide storm storage volume within the sewers leading to a treatment plant.

This can reduce or avoid the need to provide large storage tanks at the treatment plant. The HGM units can be called to release the stored flow when signalled from the WWTP. This is an acceptable practice according to the German ATV A 128, where the static pipe volume can be used to provide the necessary retention tank volume. This utilises retention volumes within the trunk sewers which would not otherwise be used.

Due to its small footprint and because of utilizing the existing pipe as a “flushing chamber” for the flush-water, HGM can be retrofit into existing systems.

The Advantages

- Long and persistent high energy flushing wave

- Flushing of long sections of pipework with single flushing shields

- Flushing of long distances (for instance 6 km) using a series of HGM units as a network

- Effective Downsurge Flush up to 2/3 of the impound range

- High flushing frequency – high flushing efficiency

- Variable flush frequency

- Variable flush volume is achievable by control

- Local or remote controlled system

- Operates independently of weather conditions

- Easy retrofit and integration in existing pipe systems

- No steps within the pipe invert

- Shield moves completely out of pipe cross-section, ensuring no loss of pipe capacity

- Shield over- and underflow possible

- No external flush water chamber necessary

- Suitable for pipe sewer management – Pipes from DN 500 up to DN 2500 (larger upon request)

- Patented